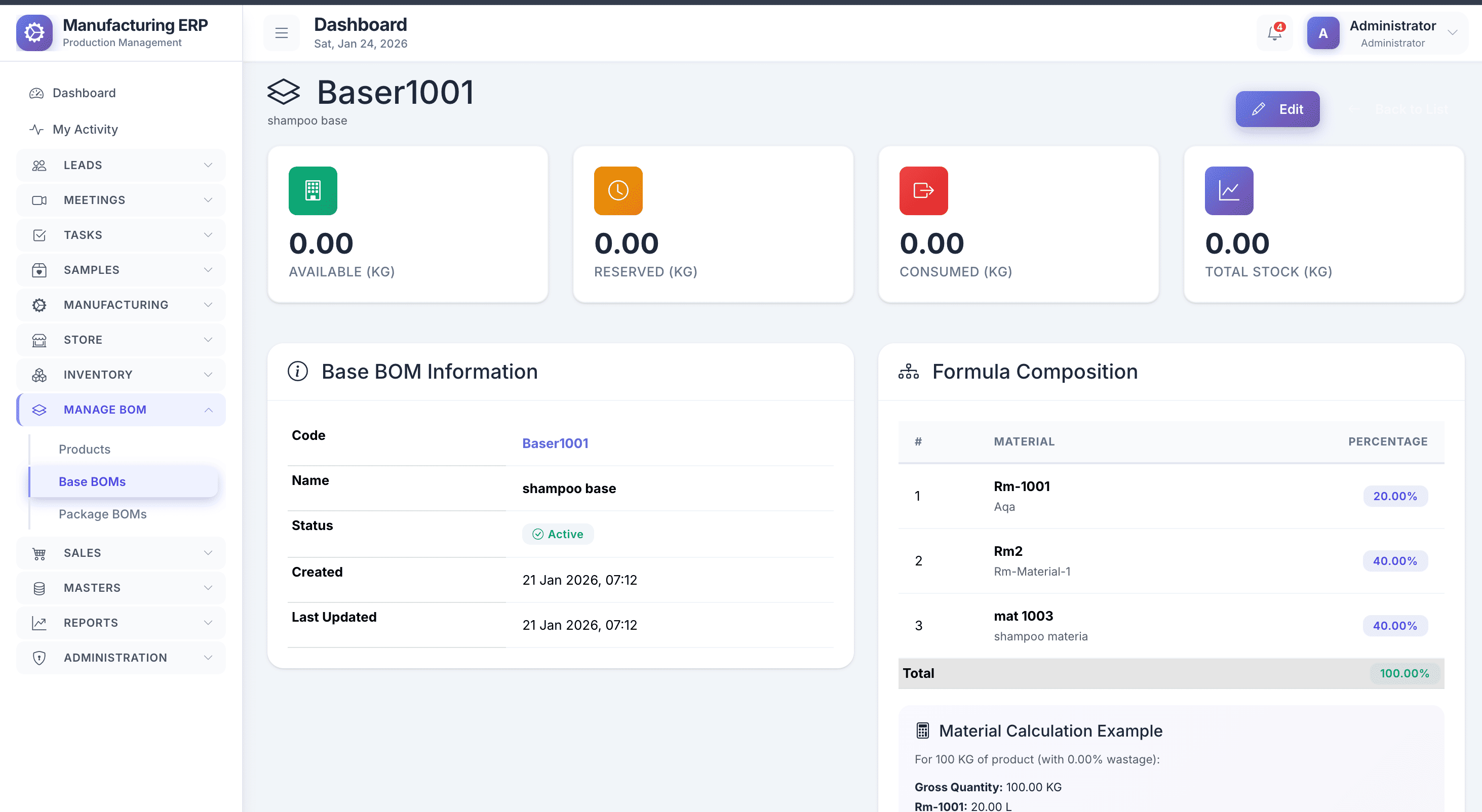

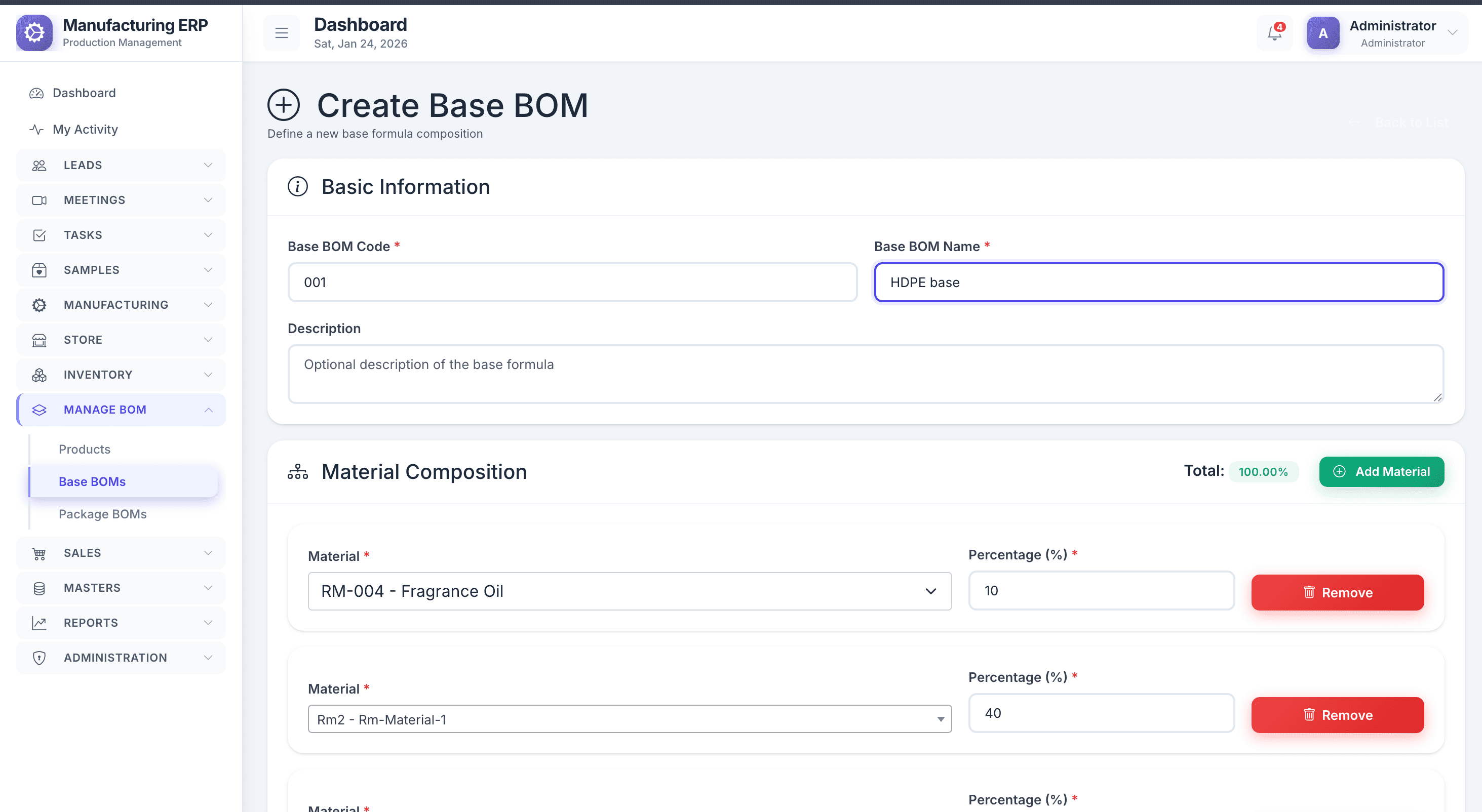

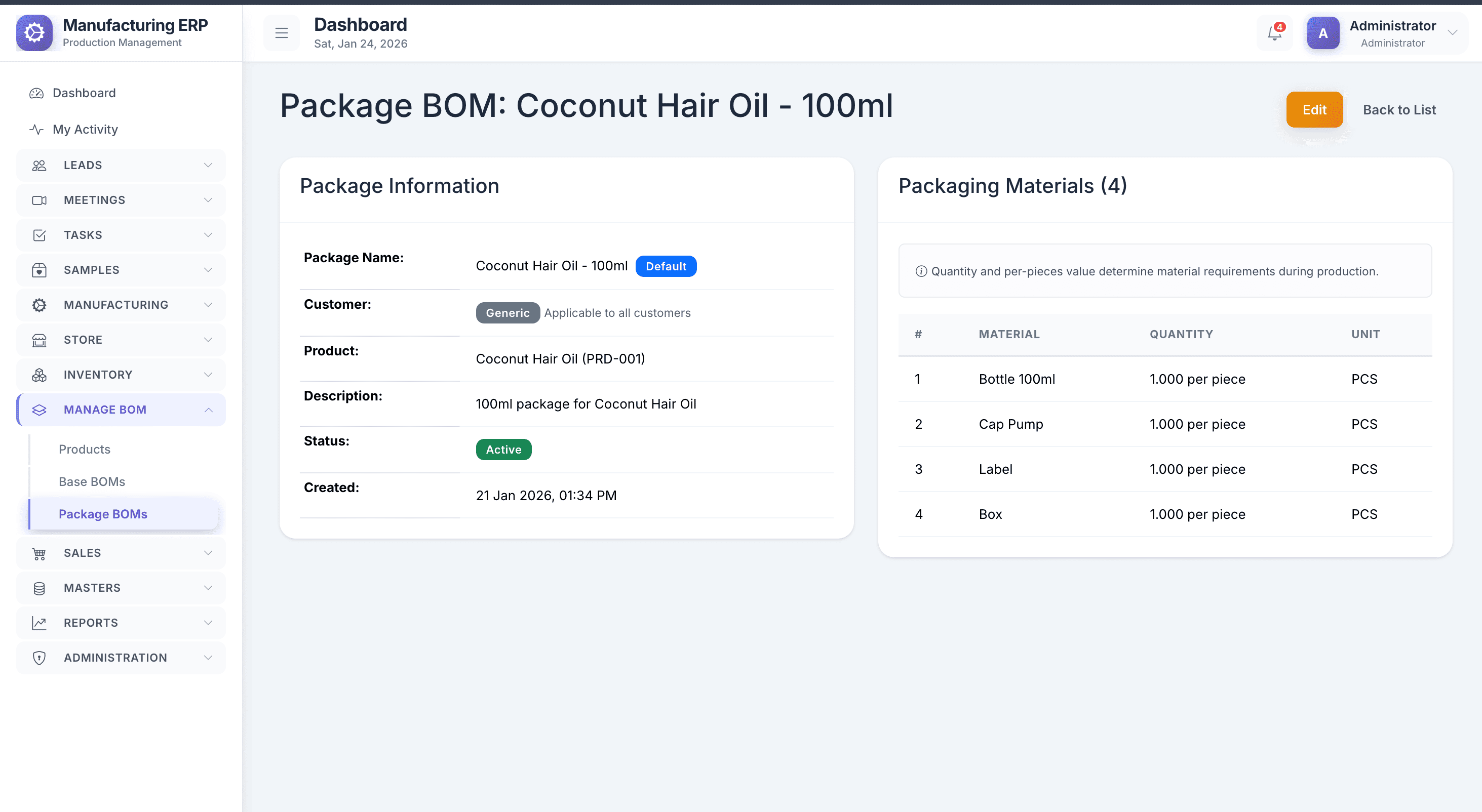

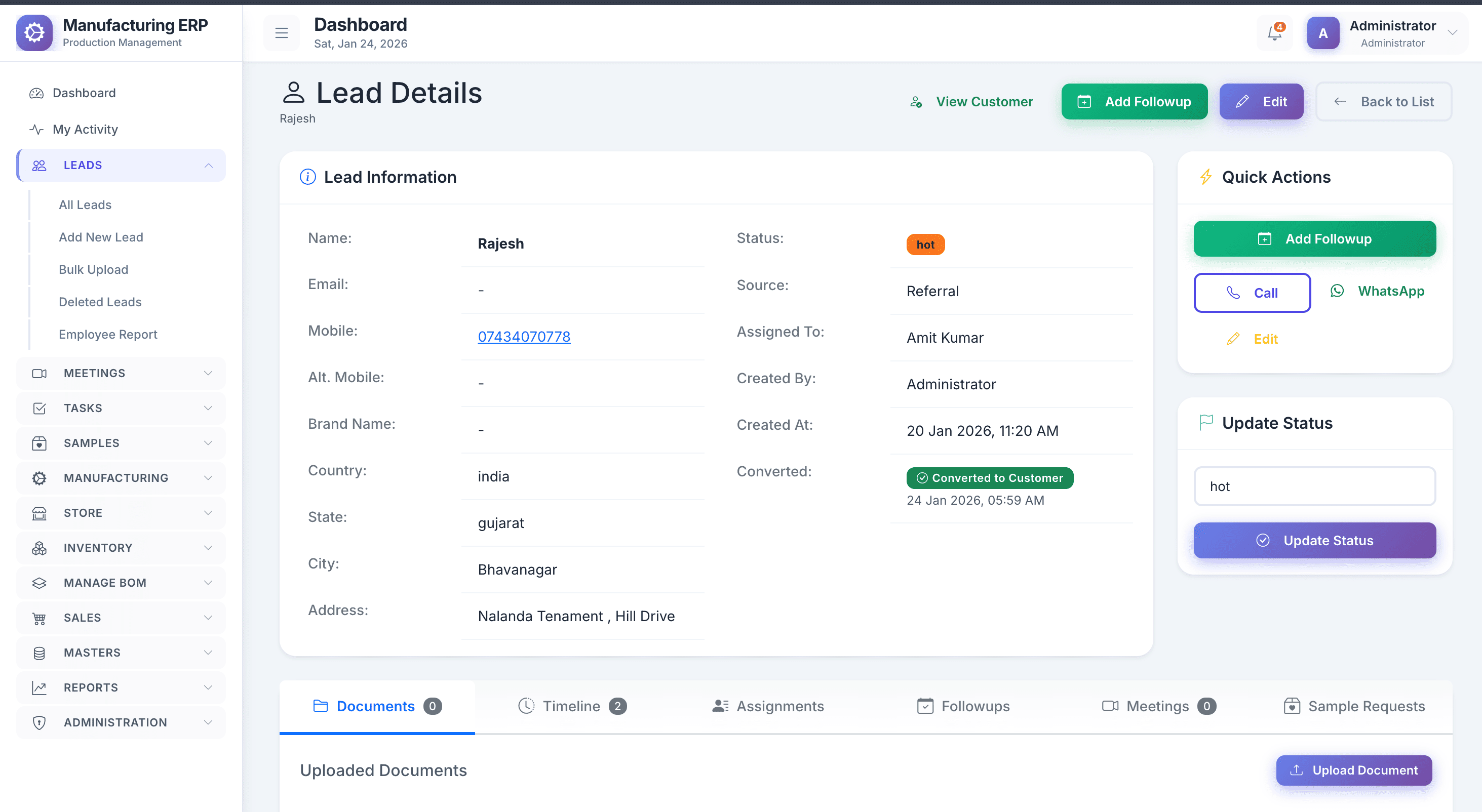

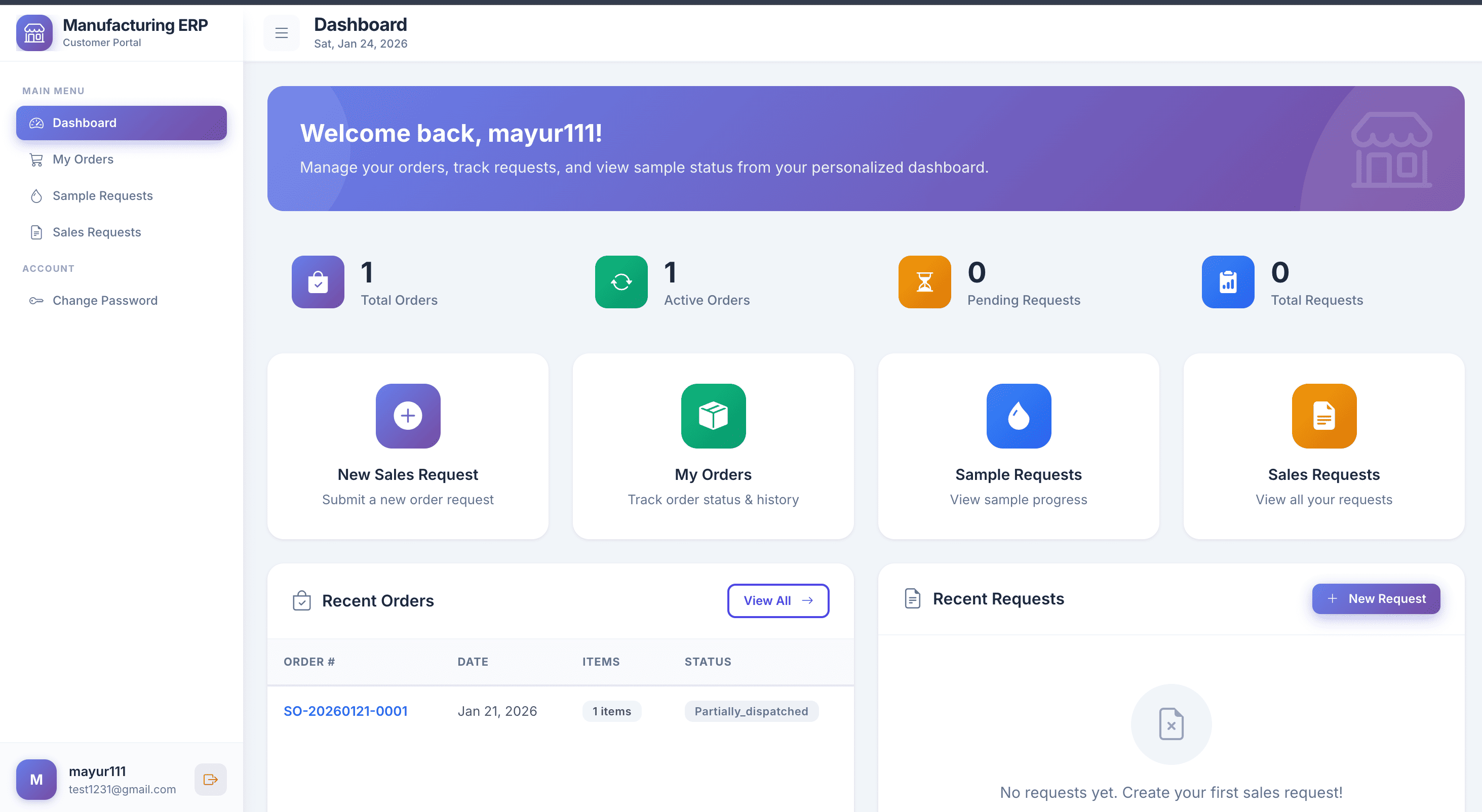

ManufactureFlow ERP is designed for formulation-based

manufacturing industries, including:

• Cosmetics & Personal Care

• Pharmaceuticals & Nutraceuticals

• Food & Beverage Processing

• Chemical Manufacturing

• Ayurvedic & Herbal Products

• Paint & Coatings

• Adhesives & Sealants

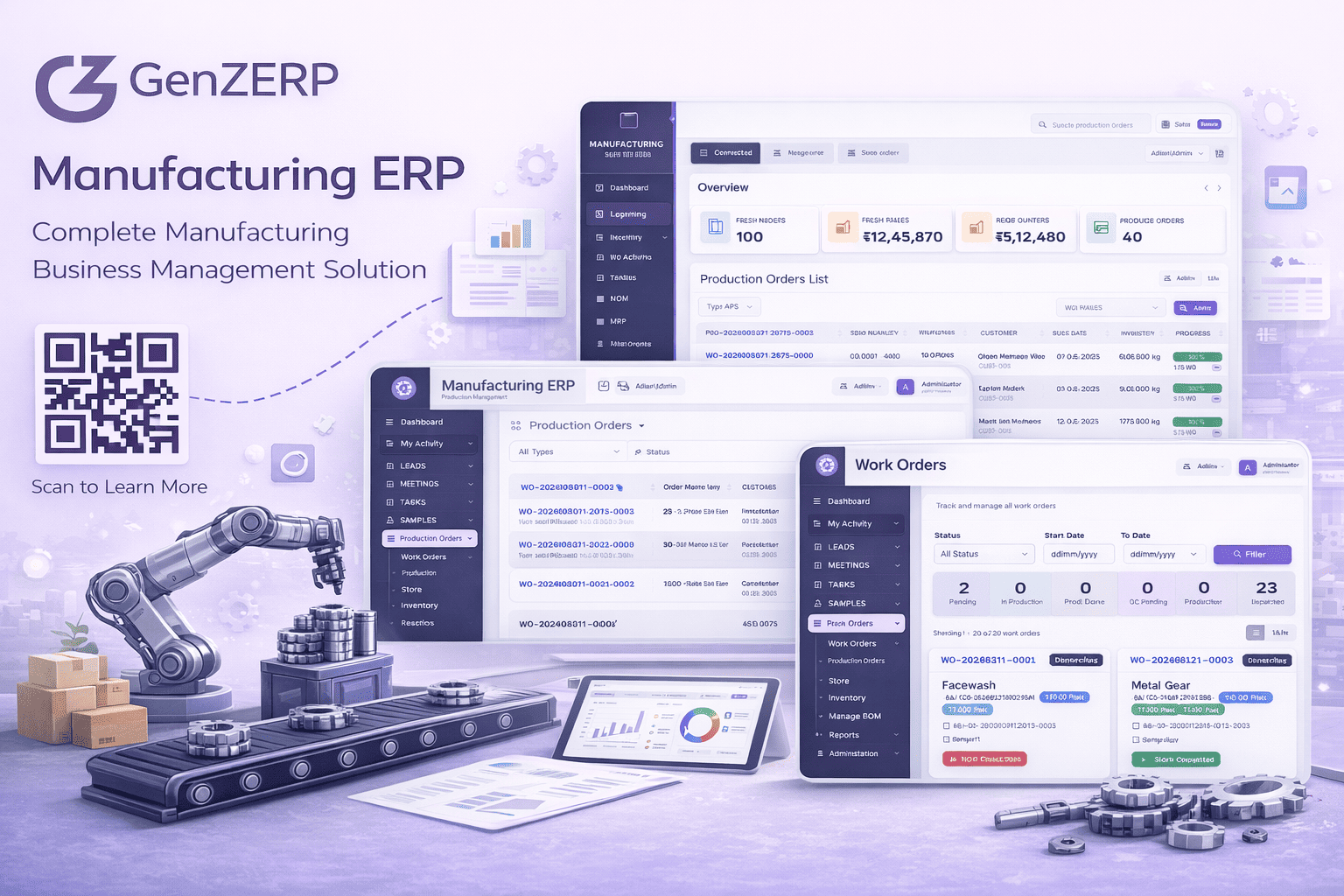

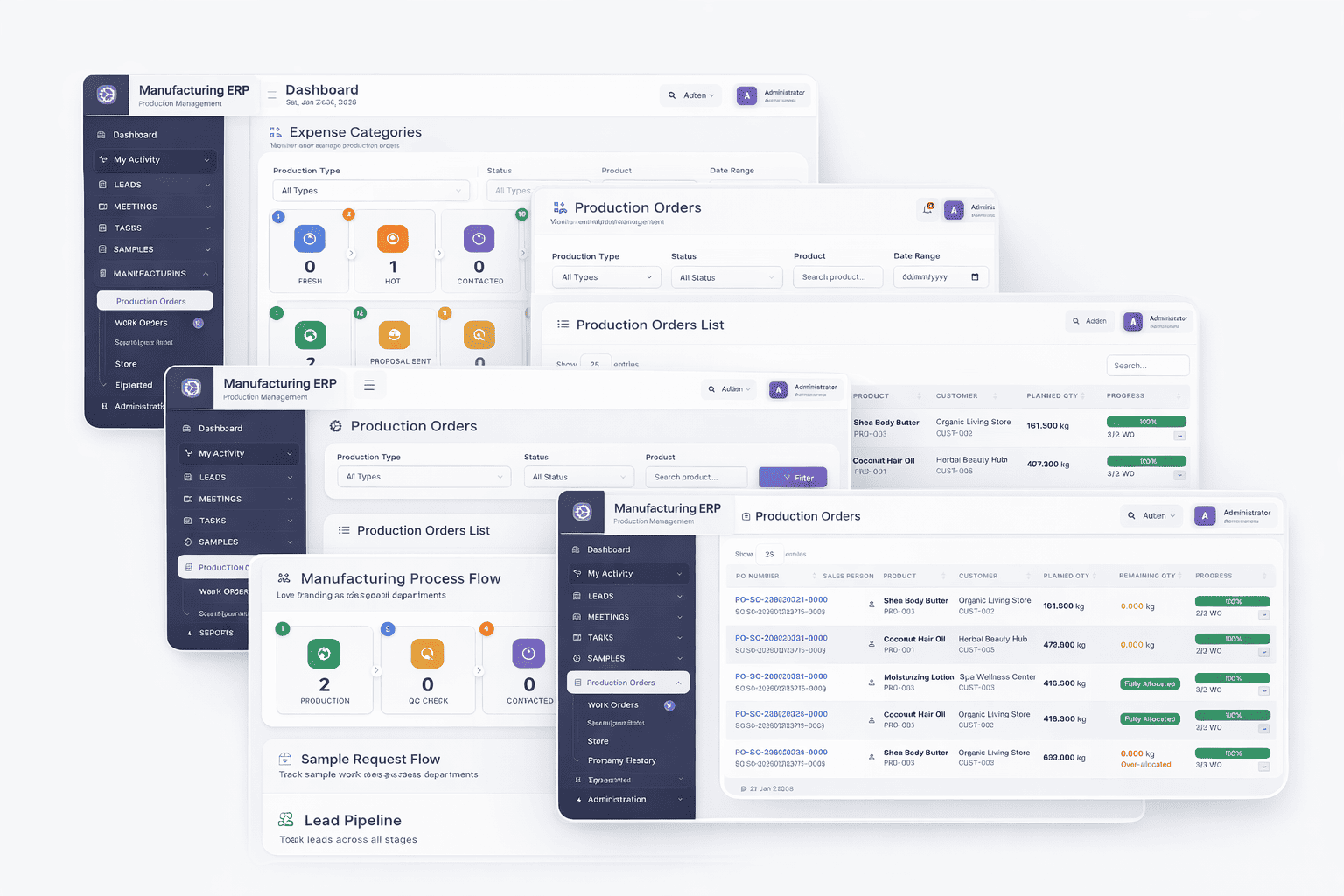

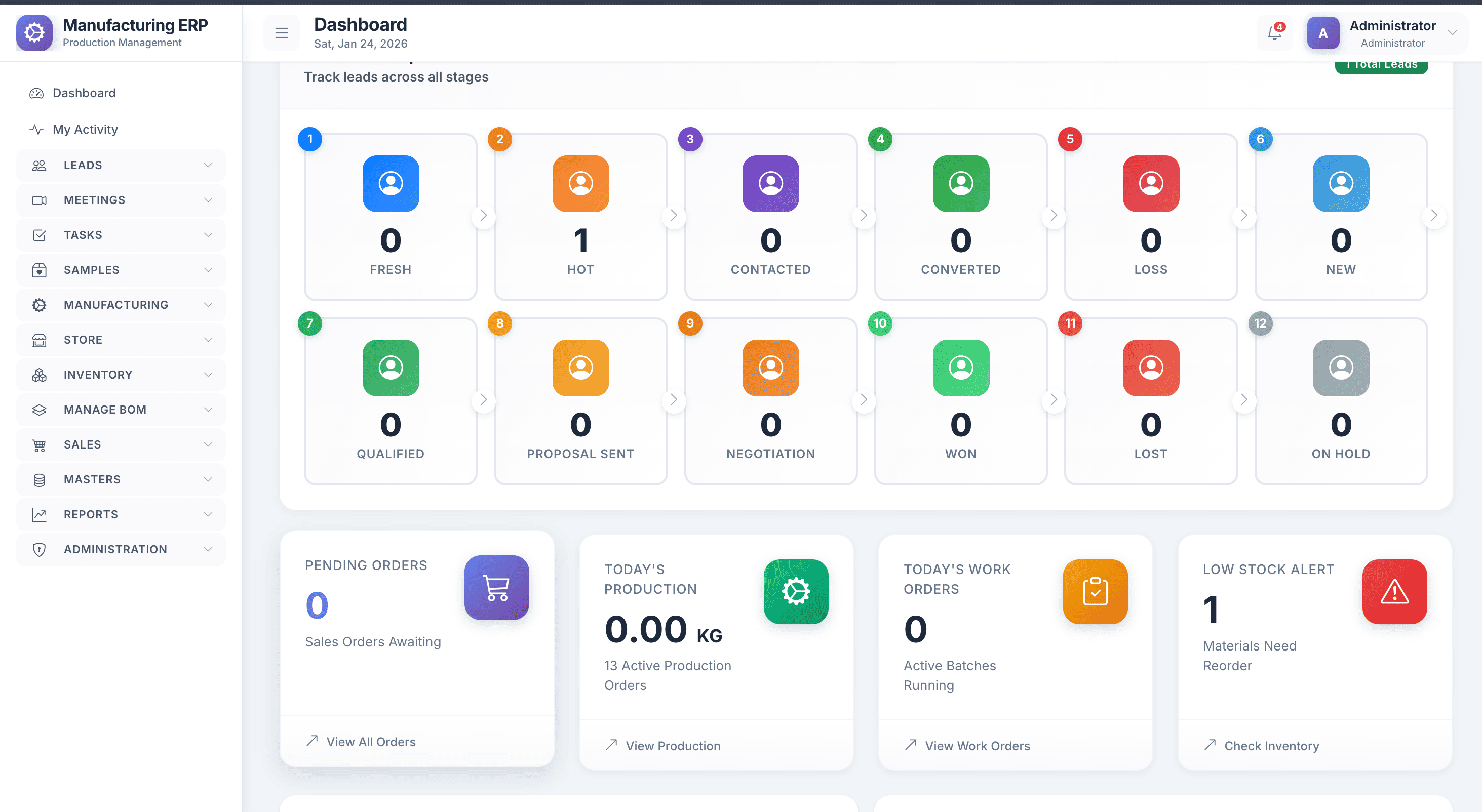

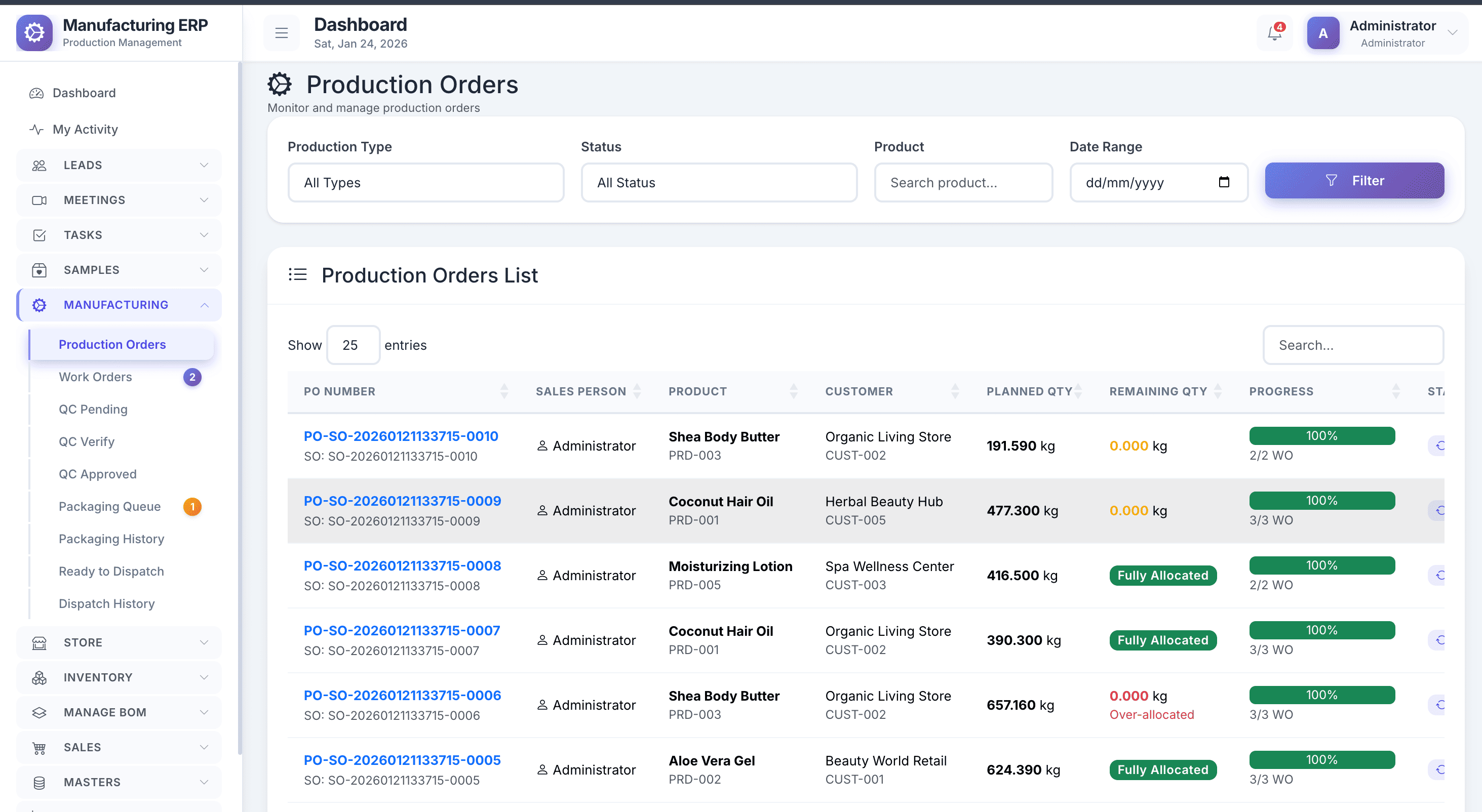

Manufacturing ERP

- Free 6 Months of Support

- Free Lifetime Updates

- 100% Money Back Guarantee

- Cloud Deployment Ready

- Optimized for High Performance